How to Find Reliable Injection Molding Services in China

So, the big meeting just wrapped up. your new project has the green light, the timeline is aggressive, and the budget is… well, let’s just say it’s tight.. Then a voice—perhaps your manager or the CFO—drops the line that gives every project manager a shock: “We should look at sourcing this from China.”

You nod, of course. It seems sensible at first glance. The potential savings can be massive. However, your brain is racing with concerns. You’ve heard all the horror stories, right? The quality disasters, the communication black holes, the shipment that shows up three months late looking nothing like the sample. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

However, here’s the reality. Sourcing plastic mold can be a calculated project. It’s simply another project with clear steps. And like any project, it succeeds or fails based on the process you follow. It’s less about finding the absolute cheapest quote and more about finding the right partner and managing the process with your eyes wide open. Disregard those scary tales. Let’s walk through a real-world playbook for getting it right.

Step One: Do Your Homework

Before searching suppliers or opening Alibaba, nail down your requirements. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. You can’t expect a factory on the other side of the world to read your mind. Sending a vague request is like asking a builder to quote you for “a house.” The responses you get will be all over the map, and none of them will be useful.

Your goal is to create a Request for Quotation, or RFQ, package that is so clear, so detailed, that it’s nearly impossible to misinterpret. It’s the cornerstone of your entire effort.

So, what goes in it?

Start with your 3D design files. These are non-negotiable. Stick to universal formats like STEP or IGS to avoid any compatibility headaches. This serves as the definitive part geometry reference.

However, 3D alone won’t cut it. Include precise 2D engineering drawings. This details critical info missing from the 3D file. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. Any seal surfaces or critical hole sizes must be clearly labeled.

After that, material choice. Don’t just say “Plastic.” Even “ABS” alone is too vague. Get precise. If you need SABIC Cycolac MG38 in black, say exactly that. What’s the reason? Because resin grades number in the thousands. Specifying the exact resin grade ensures you get the strength, flexibility, UV resistance, and color consistency you planned for with plastic mold injection.

They can offer alternatives, but you must provide the initial spec.

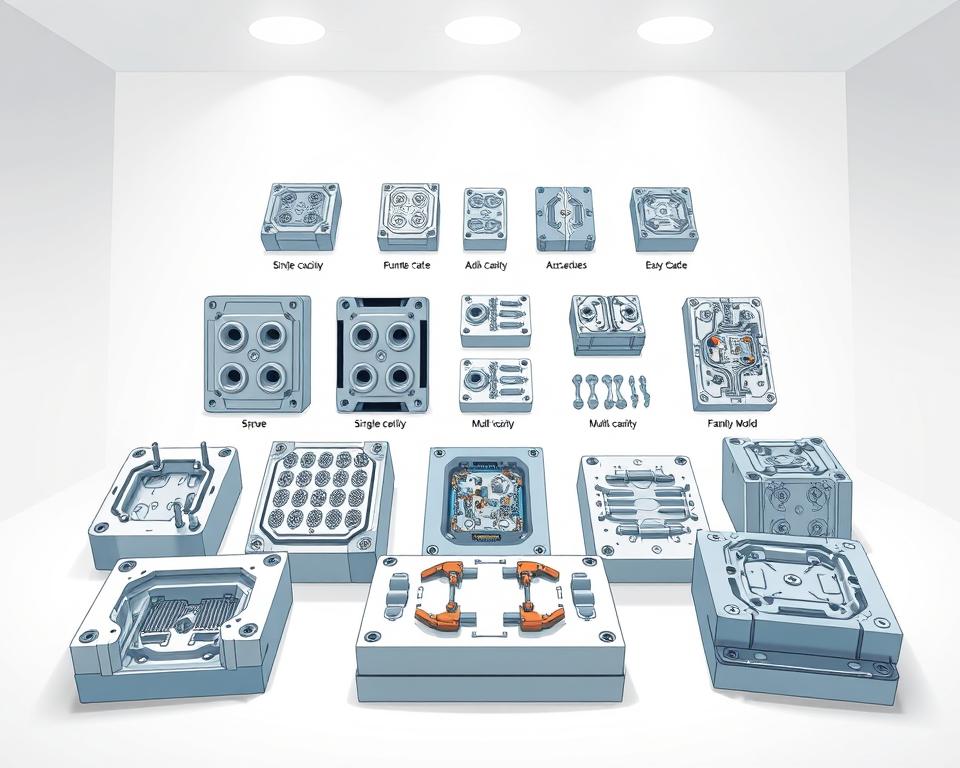

Finally, include the business details. State your EAU. They need clarity: is it 1,000 total shots or a million units per annum? Tool style, cavity count, and unit cost are volume-driven.

Finding the Right Supplier

With your RFQ perfected, who will you target? The internet has made the world smaller, but it’s also made it a lot noisier. Finding suppliers is simple; finding quality ones is tough.

You’ll probably kick off on Alibaba or Made-in-China. They offer breadth but not depth. Use them to build a shortlist, not the final list. Narrow your pool to about a dozen promising firms.

But don’t stop there. Think about engaging a sourcing agent. They do cost extra. Yet top agents deliver reliable, audited suppliers. They are your person on the ground, navigating the language and cultural barriers. For a first-time project, this can be an invaluable safety net. It’s schedule protection.

Also consider trade fairs. If you have the travel budget, attending a major industry event like Chinaplas can be a game-changer. Nothing beats a face-to-face conversation. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. Plus, ask peers for referrals. Consult trusted colleagues. A solid referral can be more valuable than any ad.

Shortlisting Serious Suppliers

Now you have your long list of potential suppliers and you’ve sent out your beautiful RFQ package. bids begin to arrive. Some will be shockingly low, others surprisingly high. Your task is to filter them down to 2–3 credible finalists.

How to proceed? It’s a bit of an art and a science.

Step one: audit communication. Are their replies prompt and clear? Do they communicate effectively in English? But the key: do they probe your RFQ? A great supplier will review your RFQ and come back with thoughts. For instance: “Draft angle here could improve mold release. Tolerance check via CMM adds cost—proceed?” Consider that a big green light. You know they know their stuff. Anyone who simply agrees to all specs is a red flag.

Then confirm their machinery specs. Get their tooling inventory. Review examples of parts akin to your design. Don’t pick a micro-molding shop for large components.

Next up: the factory audit. You can’t skip this. As you vet staff, you must vet suppliers. Either visit in person or engage a local audit service. They perform a one-day factory inspection. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. That small investment can save you thousands.

Converting Digital Designs into Molded Parts

After picking your vendor, you’ll agree on terms, typically 50% upfront for tooling and 50% upon first-sample approval. Now the real fun begins.

The first thing you should get back after sending your payment is a DFM report. Design for Manufacturability (DFM) is essential. It’s the engineering critique for moldability. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. A detailed DFM shows expertise. It’s a two-way partnership. You iterate with their team to optimize the mold.

With DFM sign-off, toolmaking begins. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These represent the first trial parts. It’s your first real test.

T1 parts usually require adjustments. That’s standard process. There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You’ll provide detailed feedback, they’ll make small adjustments (or “tweaks”) to the tool, and then they’ll send you T2 plastic mold company samples. You may repeat this cycle a few times. Build buffer time for sample iterations.

Eventually, you will receive a part that is perfect. Dimensions, finish, and performance all check out. This is now the benchmark sample. You sign off, and it serves as the master quality reference.

Crossing the Finish Line

Getting that golden sample feels like the end, but it isn’t. Now you’re entering the mass production phase. How can you keep part #10,000 matching your golden sample?

Put a strong QC process in place. Typically, this means a pre-shipment audit. Again, you can hire a third-party service. For a few hundred dollars, they will go to the factory, randomly pull a statistically significant number of parts from your finished production run, and inspect them against your 2D drawing and the golden sample. They provide a photo-filled inspection report. Only after you approve this report do you authorize the shipment and send the final payment. This audit shields you from mass defects.

Finally, think about logistics. Clarify your Incoterms. Are you on FOB terms, where they load and you take over? Or EXW, shifting all transport to you? These details have a big impact on your final landed cost.

Sourcing from China is a marathon, not a sprint. It hinges on strong supplier relations. See them as collaborators, not vendors. Open dialogue, trust, and rigorous procedure deliver results. No question, it’s demanding. However, armed with this guide, you’ll secure savings and keep high standards intact. You’ve got this.